BorgWarner has won a new contract to deliver dual inverters to a leading Chinese original equipment manufacturer (OEM) for use in hybrid vehicles. This agreement builds on the companies’ previous dual inverter collaboration in 2021. Mass production for the new project is expected to start by the end of 2025.

“We are pleased to once again win dual inverter business from this important customer. This milestone signifies a new phase of collaboration in the new energy vehicle sector,” said Dr. Stefan Demmerle, Vice President of BorgWarner Inc. and President and General Manager, PowerDrive Systems. “In China’s rapidly evolving NEV market, BorgWarner remains committed to supporting our customers with innovative and high-quality electrification solutions.”

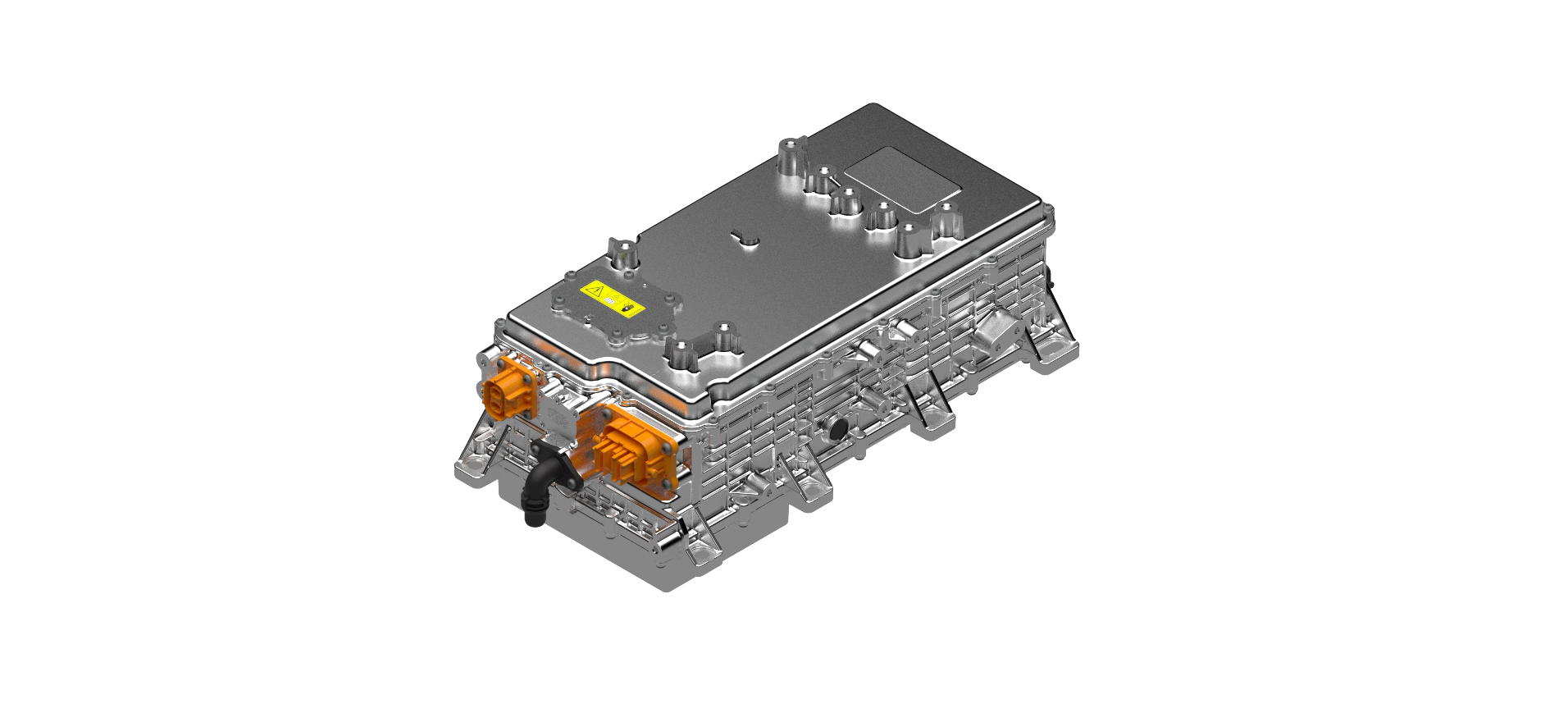

BorgWarner’s dual inverter enables synchronous control of two motors using a single controller, enhancing packaging flexibility and simplifying installation. Utilizing BorgWarner’s proprietary packaging technology, power modules can be configured flexibly, with various modules integrated into a compact unit—effectively reducing both weight and cost.

BorgWarner’s dual inverter technology features an advanced power module design that reduces thermal resistance by up to 50% compared to single-sided cooling, significantly boosting power density. The technology also enables the integration of various types of semiconductor dies within modules of the same size, supporting compliance with stringent China Light-Duty Vehicle Test Cycle (CLTC) efficiency standards. Its adaptive battery voltage regulation extends the motor’s constant power and high-efficiency operating ranges, enhancing overall system efficiency.

COMMENTS