FUJIFILM Corporation announces the launch of “Prescale for High Temperature 100/200”, a pressure measurement film designed for heat pressing processes in semiconductor and automotive manufacturing, available from October 15, 2025.

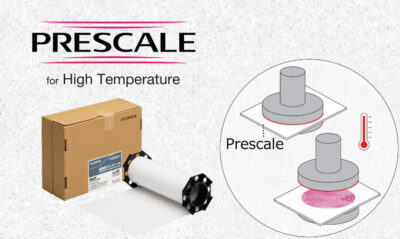

“Prescale” is a film that enables easy measurement of contact pressure, pressure balance, and distribution between contacting surfaces. The film consists of a color-forming layer and a developer layer. When pressure is applied, microcapsules in the color-forming layer breaks according to the pressure, causing the enclosed color-forming materials to transfer to the developer layer. The red color appears as a result of chemical reaction between the two materials. Furthermore, the color density varies depending on the magnitude of the pressure, allowing users to visually confirm both the pressure distribution and pressure values across the entire surface using color charts and calibration curves. This dependable and visually interpretable pressure indication makes “Prescale” a valuable tool across a wide range of industries, including displays, electronic components, automotive, batteries, and packaging. It is widely used in both development and manufacturing processes to enhance inspection efficiency and quality control.

In recent years, the application of “Prescale” has become increasingly diversified, driven by the advancement of manufacturing processes and growing demands for quality assurance and traceability. There is a rising need for high-accuracy pressure measurement under heated conditions in processes such as automotive press molding, heat sealing in pharmaceutical and food packaging, and wafer bonding in semiconductor manufacturing.

Fujifilm has launched “Prescale for High Temperature 100/200”, a new pressure measurement film designed for heat pressing inspections up to 220°C. By leveraging Fujifilm’s unique high-precision coating technology and advanced microcapsule design technology, and incorporating a heat-resistant base material, “Prescale for High Temperature 100/200” enables highly accurate and stable pressure measurement even under high temperature environments.

Unlike conventional methods that require equipment to be cooled before pressure inspection, “Prescale for High Temperature 100/200” enables direct measurement in high temperature environments. This eliminates the need for cooling and reheating steps, minimizing equipment down-time and contributing to improved inspection efficiency and overall productivity.

In addition, “Prescale for High Temperature 100/200” is now supported by the mobile app “Prescale Mobile” which analyzes color-developed “Prescale” images and converts pressure into numerical data. Along with pressure quantification, the app also features an automatic pass/fail judgment function based on user-defined inspection criteria, further enhancing the quality of pressure inspection in heat pressing processes.

Fujifilm contributes to improving and stabilizing customers’ manufacturing quality by developing and providing products that enable the digitalization and optimization of inspection operations in development and manufacturing sites.

- Processing method in which heat and pressure are simultaneously applied to materials to perform molding, bonding, or sintering.

- Film that utilizes Fujifilm’s precision coating technology and microcapsule technology to easily visualize the balance and distribution of pressure and surface pressure. Recommended usage temperature: 20°C to 35°C.

- Process in which multiple wafers or chips are bonded together.

- Mobile application that quantifies pressure from the color-developed image of “Prescale” using Fujifilm’s advanced image processing technology. By placing the developed “Prescale” on a dedicated calibration sheet and scanning it with a mobile device installed with the app, users can easily obtain 13 types of pressure data such as maximum/minimum pressure, average pressure, and pressure area. This simple workflow enables anyone to perform high-precision pressure inspection with ease.

COMMENTS