LG Electronics is entering the semiconductor equipment market with a focus on developing critical machinery for manufacturing high-bandwidth memory (HBM) chips, which are vital for AI technologies, according to a report by the Korea Herald.

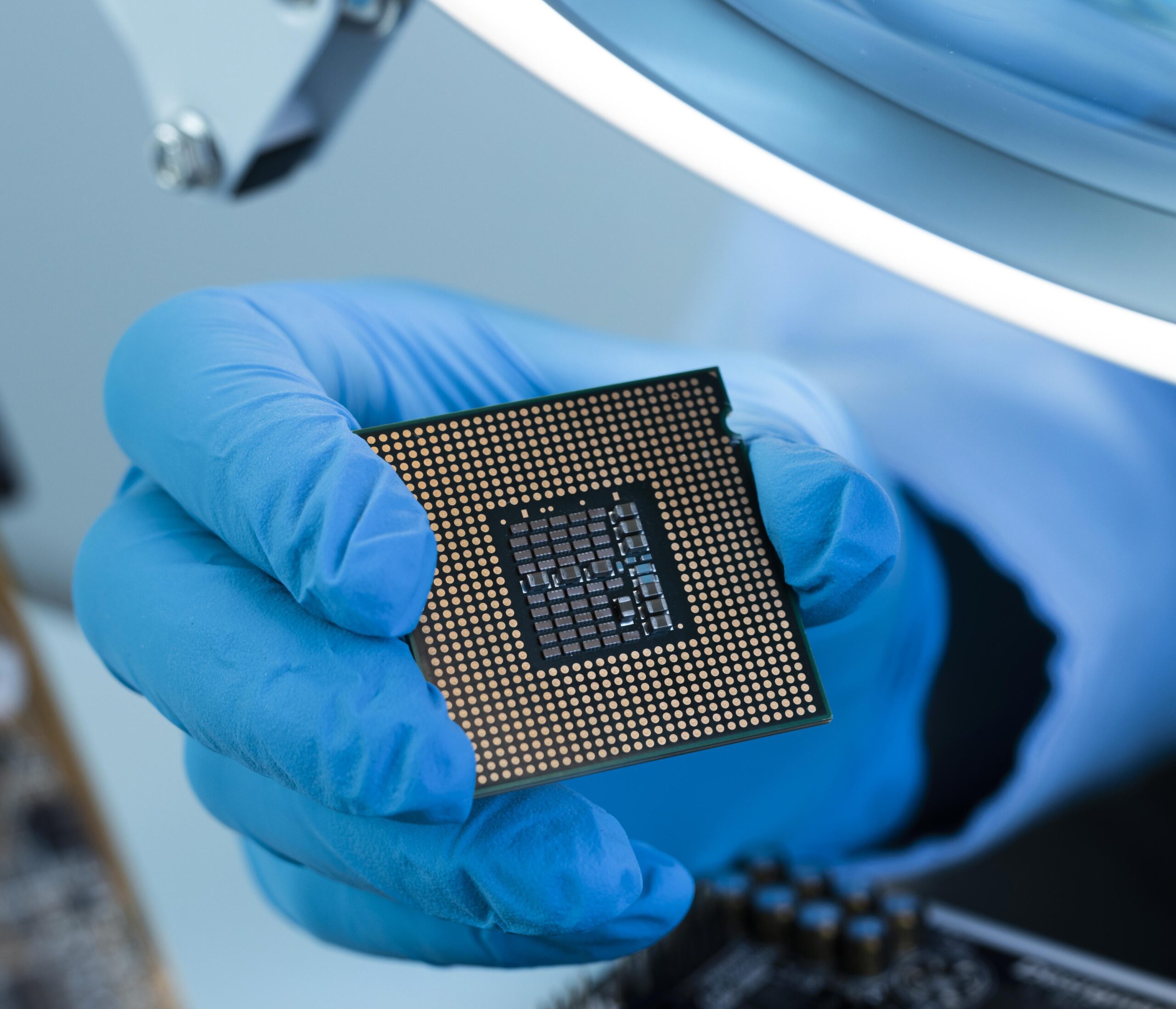

LG Electronics has confirmed that its in-house R&D arm, the Production Engineering Research Institute, is developing a hybrid bonder — an advanced chip packaging machine used in the production of high-bandwidth memory (HBM) chips critical for AI applications.

While media reports, including one by the Korea Herald, indicated a potential commercialisation target of 2028, the company clarified that development is ongoing and no definitive timeline for mass production has been established.

Semiconductors hold a complex legacy for LG. The company lost its chipmaking division, LG Semicon, during the 1997 Asian financial crisis following a government-mandated merger with Hyundai Electronics — now SK hynix.

Despite this setback, LG has remained active in semiconductor innovation, focusing on custom chip design for its own products and recently partnering with Canadian AI chipmaker Tenstorrent to deepen its capabilities in the AI hardware space.

LG’s Production Engineering Research Institute has been actively involved in HBM-related technologies, offering packaging and testing equipment for advanced semiconductor applications. This renewed focus is in line with LG Group Chairman Koo Kwang-mo’s broader AI strategy, as the company positions itself to meet the surging global demand for AI chips.

“LG is entering the market because there’s clear business potential,” said Lee Jong-hwan, a professor of system semiconductor engineering at Sangmyung University. “HBM is expected to see continued growth because it is a critical component in AI chips, which are becoming dominant in the market.”

Lee noted that the Production Engineering Research Institute has long handled equipment and systems related to mass production.

“So they have strengths in developing related tools. That’s why they are confident in commercialising this technology,” Lee said. (ANI)

COMMENTS