Image Courtsey- https://electrical-engineering-portal.com/systems-motion-motor-drive

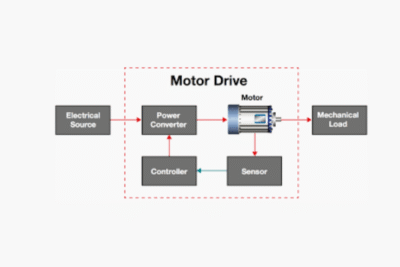

Quantum Power Transformation (QPT) Ltd, a Cambridge-based company founded in 2019 and specializing in gallium nitride (GaN)-based electric motor controls, has introduced MicroDyno — a low-voltage motor drive test platform designed to showcase the advantages of ultra-high-frequency GaN motor drives. The solution delivers higher efficiency, improved control, and reduced system complexity and cost, offering strong benefits for the rapidly growing cobot market.

Operating at 1MHz switching speeds, MicroDyno features a compact filter that produces a true sine-wave voltage for motors — a clear differentiator compared to traditional low-frequency PWM systems.

Although QPT’s technology can scale to very high power levels, this low-voltage platform highlights its potential to transform cobots and robotics. By dynamically correcting torque cogging and torque ripple and enabling high-fidelity sensing within the drive, MicroDyno achieves superior performance without the need for costly external sensors or encoders. This approach both reduces overall system costs and delivers significant performance gains over conventional PWM-based solutions.

“Even the best servos can have horrid cogging torque,” comments InnCat’s director & chief technology innovation officer (CTIO) Simon Hart. “I have spent much time with fast control loops and torque compensators to get the required speed smoothness. And then loop responses drift over time!”

Breaking Frequency Barriers

Conventional robotic drives typically run at 4–16 kHz PWM frequencies, shaping current into a sine wave but leaving the motor voltage as high dv/dt PWM. Even specialist systems that push up to 100 kHz still face electromagnetic challenges and cannot enable the compact, cost-effective filtering needed for true sine-voltage output.

MicroDyno changes this. By harnessing the full potential of GaN transistors, it operates at nearly 100x higher frequencies. This allows for a tiny, inexpensive output filter that delivers a clean sine voltage directly at the motor terminals with an extremely high signal-to-noise ratio. The result: no EMI, reduced bearing currents, sensorless operation, unshielded cabling options, and the possibility of fully integrated motor drives — a breakthrough for robotics design.

Key Advantages for Cobots and Precision Robotics

-

Dynamic Torque Ripple & Cogging Correction

Using QPT’s qSense technology, MicroDyno compensates in real time for torque disturbances in both time and frequency domains. It surpasses encoder-based static correction methods, which drift over time and cannot respond dynamically. -

Unprecedented Smoothness

With qControl technology, the drive generates 1 MHz signals with picosecond precision. Tiny filters produce true sine voltage for cleaner control signals, enabling smoother motion vital for delicate assembly and medical robotics. -

Sensorless Diagnostics

Clean sine-wave output supports advanced torque and vibration monitoring, allowing the drive itself to detect and diagnose vibration causes without external sensors. -

Compact & Lightweight

High-frequency switching shrinks filter and drive size, enabling full integration into robotic joints. -

Lower Costs & Simplified Systems

Eliminates the need for shielded cabling, simplifies EMC, extends motor life, removes the need for encoders and sensors, and allows higher performance with lower-cost motors. -

AI-Ready for Next-Gen Robotics

Designed for local AI processing and cloud-based fleet monitoring, MicroDyno enables smarter, self-optimizing motor systems across robotics and machine tools.

Scalable Across Voltage and Applications

Currently demonstrated at 48V for robotics and cobots, MicroDyno’s architecture scales up seamlessly to 400V and 800V systems using QPT’s qAttach packaging. This opens applications in industrial automation, HVAC, and electric vehicle traction drives.

Its sine-wave architecture also supports multi-phase modules that can be paralleled to reach megawatt power levels, reducing complexity for motor drive OEMs.

A Foundation for the Future of Motor Drives

With electric motors consuming nearly 45% of global electricity, eliminating PWM-related inefficiencies, wear, and noise is critical. MicroDyno represents more than just a demonstrator — it lays the foundation for an entirely new class of motor drives, transforming everything from high-precision robotics to industrial megawatt-scale systems.

“MicroDyno shows what becomes possible when you combine ultra-fast GaN switching with intelligent filtering,” says QPT’s chief technology officer & founder Rob Gwynne. “For robotics, we’re not just improving smoothness. We can now dynamically correct torque ripple and cogging in real time, something that even expensive encoder-based systems cannot do to this level of precision. This opens the door to more precise, more compact and more reliable robots at a much lower system cost.”

(This content is sourced from a syndicated feed. The Japan India Manufacturing Journal website assumes no responsibility or liability for its accuracy, completeness, or content.)

COMMENTS